Our Strengths

An All-round Player in Cutting Work

For our customers’ satisfaction and peace of mind

A technical group with a wealth of knowledge and experience

- Highly skilled craftsmanship

- Ability to meet customers’ needs

“Cutting metals, adding high quality, and responding to customers’ needs through speed and price” – this is our mission. Ohkawa Corporation’s craftsmen have accumulated a wealth of experience and knowledge. By responding to any request with spirit and a passion for “making the impossible possible,” we are “making dreams come true.”

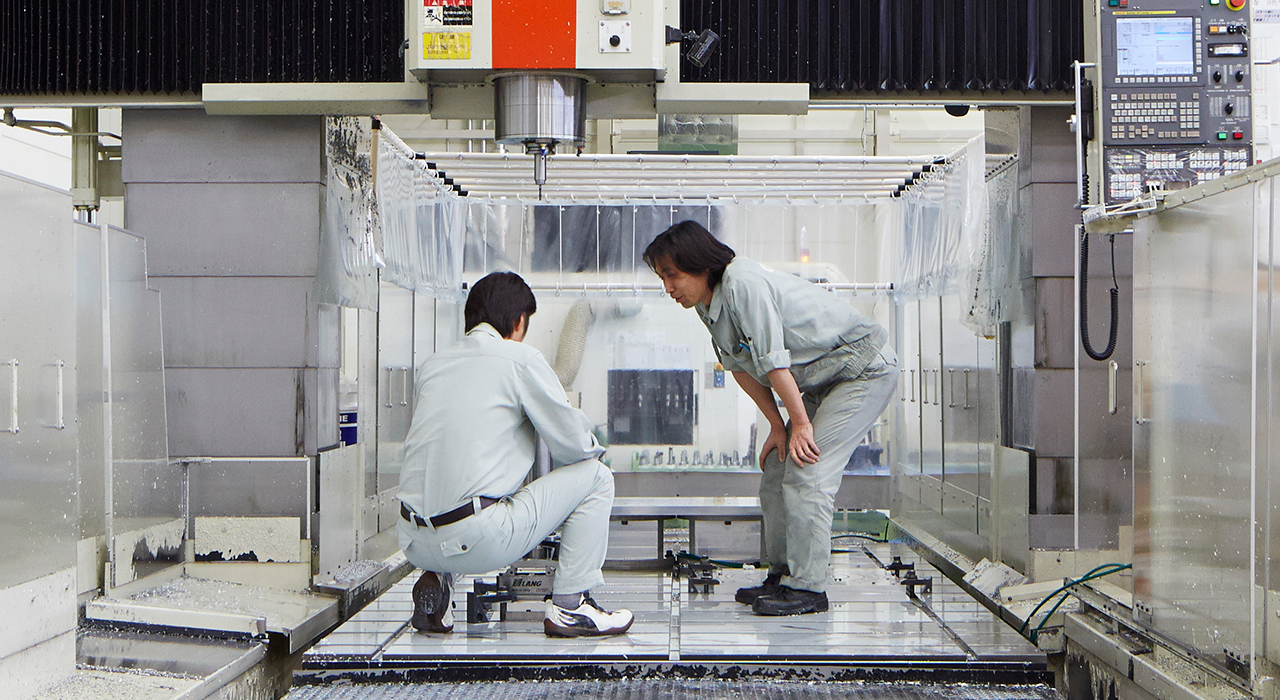

Ohkawa Corporation’s manufacturing technology incorporates state-of-the-art systems with the intention of always enhancing processing technologing and production systems that pioneer the development of society and the times. In conducting manufacturing, our engineers gather to hold review meetings and conduct repeated thorough analysis and simulation. Such teamwork aimed at realizing mutual improvement is Ohkawa’s strength and pride.

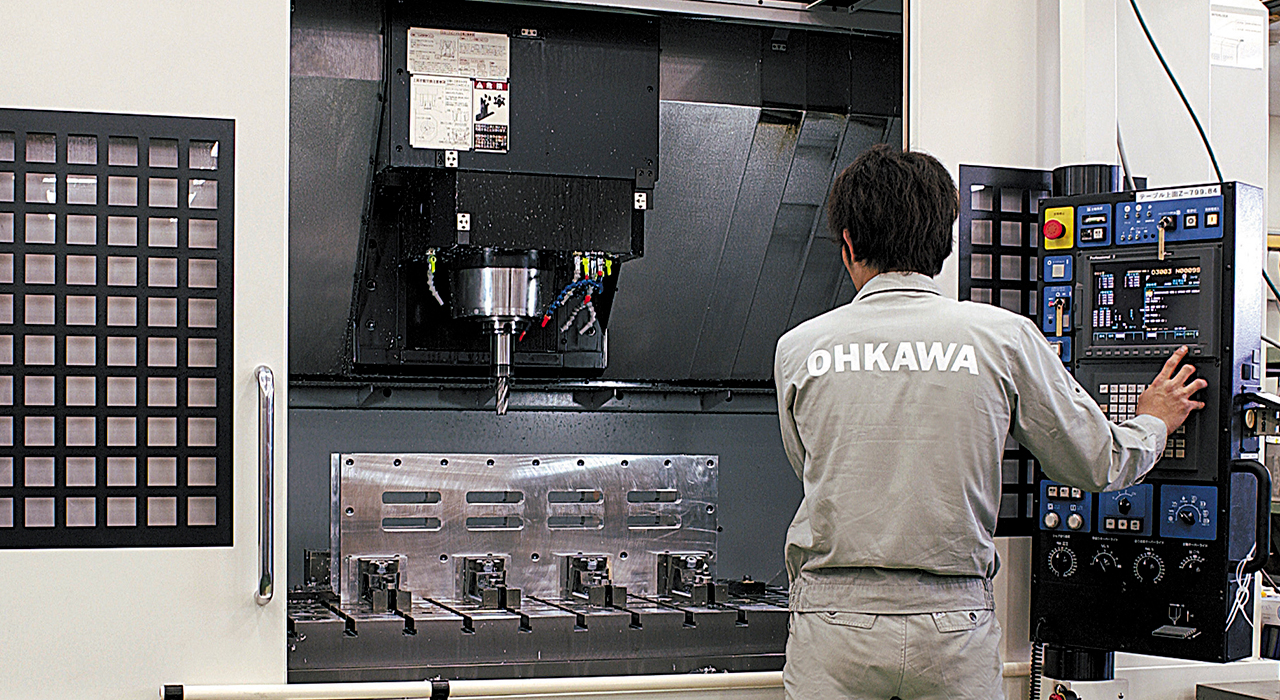

Ohkawa Corporation devotes effort to maintaining the best possible equipment and training human resources. Unless people are nurtured, there can be no technological innovation. To respond to the increasingly sophisticated and complex needs of customers and conduct manufacturing that surpasses expectations, Ohkawa’s team of engineers continues to pursue untiring self-improvement.

An All-round Player in Cutting Work

- From micromachining to large-scale machining

- From individual products to large lots

- From aluminum to machining-resistant materials

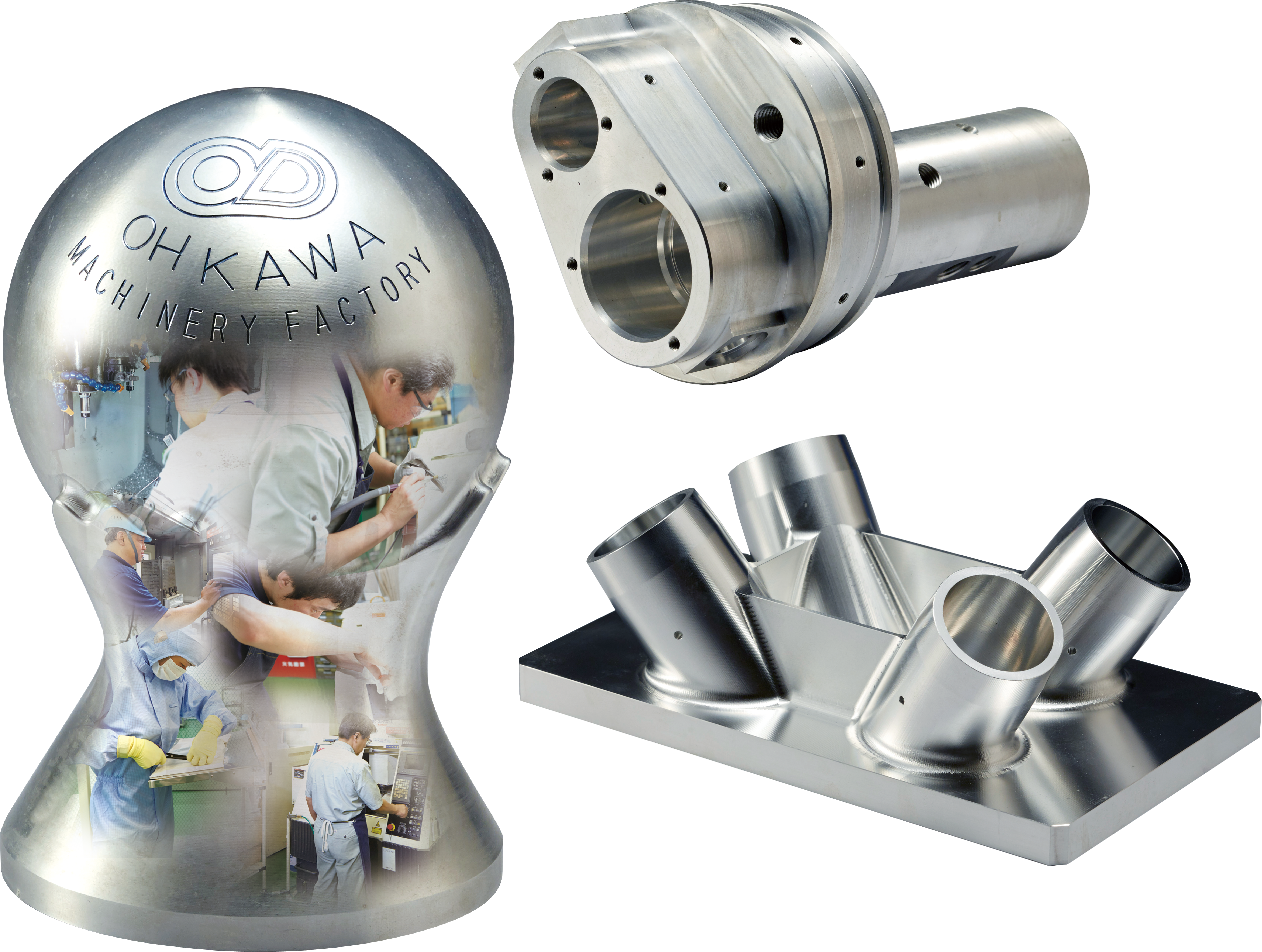

- From communications equipment to aerospace components

Ohkawa Corporation has an extensive track record of manufacturing and assembling precision machine parts in a wide variety of fields including semiconductor and liquid crystal manufacturing machines, aircraft instruments, communication devices for loading in satellites, mobile and wireless communication devices, medical instruments, and other various industrial instruments. From micromachining to the aerospace industry, Ohkawa Corporation manufactures over 10,000 products and components for a diverse range of fields. These products represent the crystallization of abundant experience and unique production technologies. Manufacturing as many products as there are needs, we aim to support the state-of-the-art technologies of the future.

Main manufacturing and processing technologies

- Machining center processing

- Lathe processing

- Electric discharge machining

- Precision cleaning

Processed metals

- Aluminum, brass, copper and other light metals

- Stainless steel, titanium, molybdenum and other machining-resistant materials

- Heat resistant alloys, such as Inconel® and RENE®

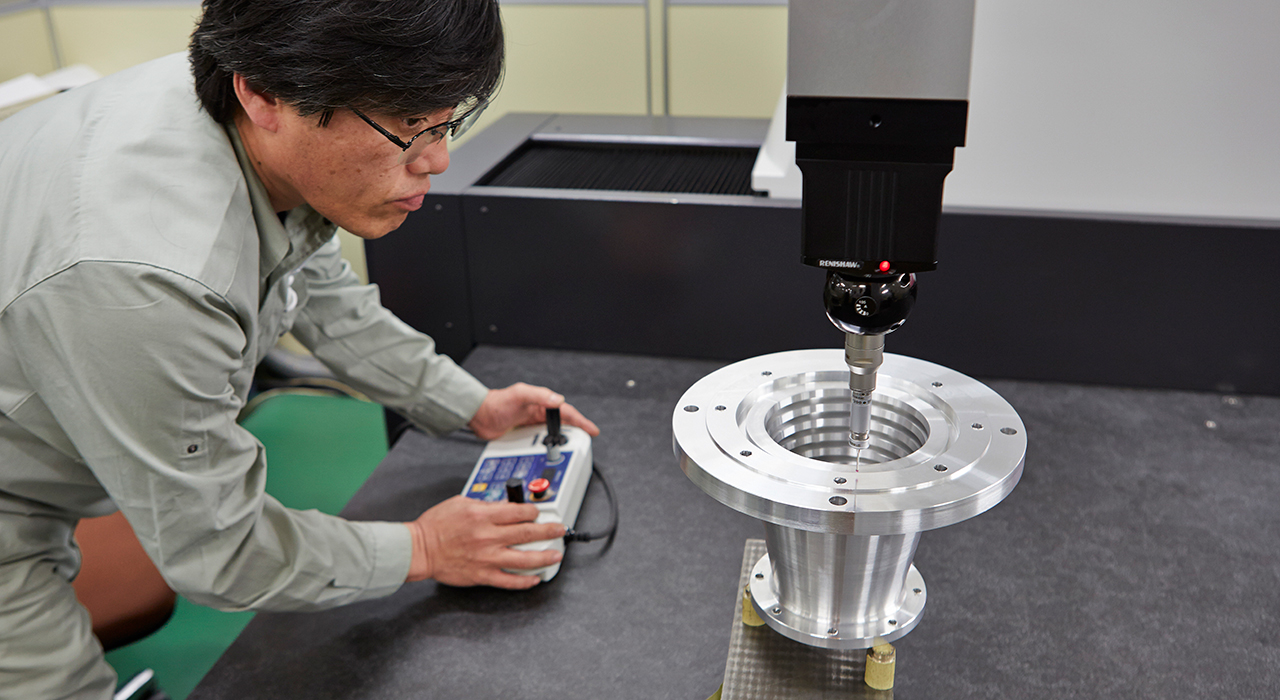

Robust Quality Assurance

- Highly secure quality assurance systems

- Thoroughgoing production management

Quality is the very essence of Ohkawa Corporation. We conduct thorough quality assurance and production management in our efforts to realize “zero-defect” products and provide 100% satisfaction to our customers.

Quality assurance is the major premise for a company to be trustworthy. We view quality as the crystallization of “a company’s technological capabilities”, “the awareness of employees”, and “organizational management capacity”. Every employee handles products with the utmost care. In manufacturing processes, work is conducted based on the awareness that “products are quality building” based on a systematized quality and technology control system, and we focus efforts on “zero-defect” production systems while pursuing thorough “built-in quality” in each production process.

In addition to quality assurance, we also regard speedy production management as one of our strengths. Every employee works under the motto of “making good products faster and cheaper”, which is the starting point for our manufacturing. Rather than resting on our laurels, we seek the best and fastest possible manufacturing by repeating analysis, improvement and implementation from various angles geared to improving production efficiency and shortening lead times.

Major Manufacturing Technologies and Processing Technologies

- Company-wide quality assurance based on our Quality Management System

- Product quality and process capabilities combining processing technologies and measuring technologies

High Quality / Low Cost / Quick Delivery / Excellent Service

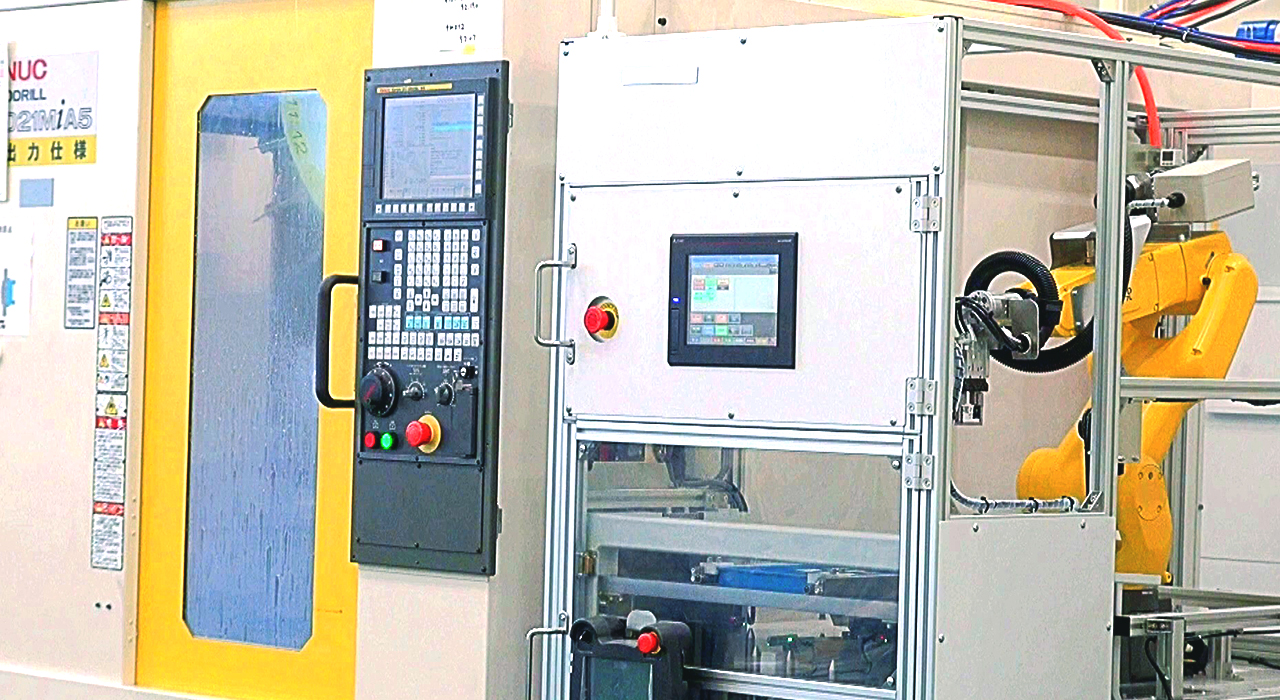

- Automated systems & 24-hour operation

- Consistent service provision

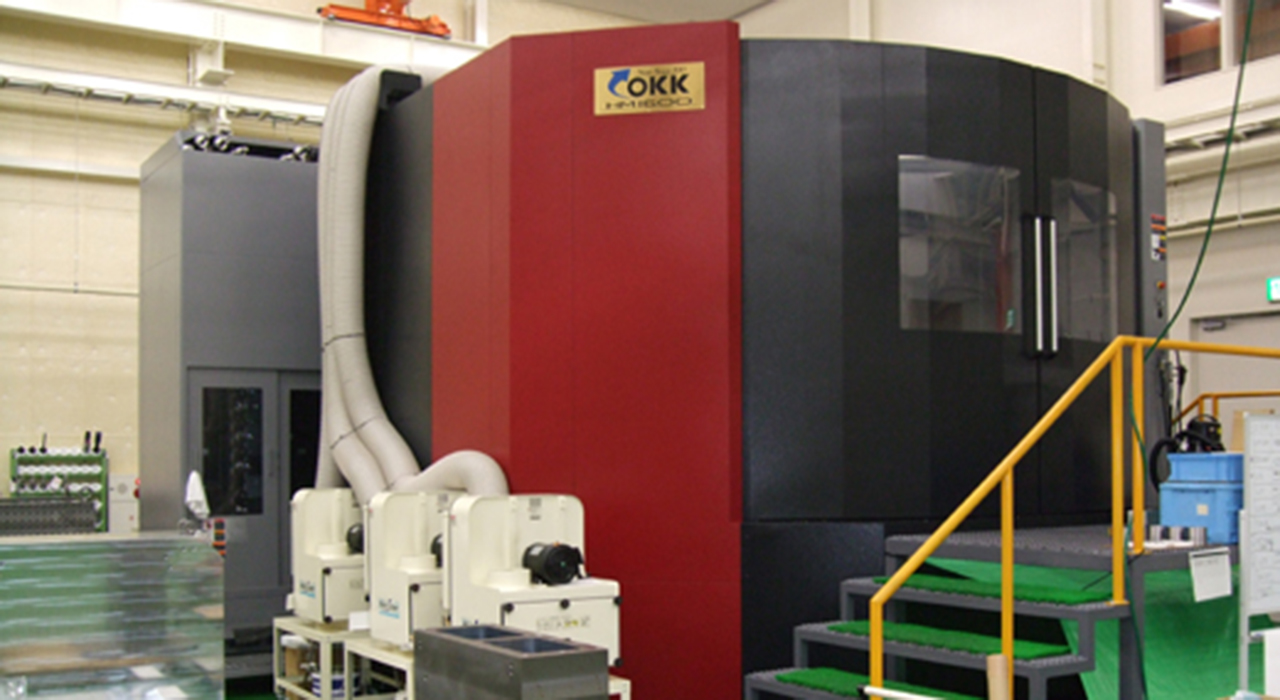

Devising methods geared to quickly supplying high-quality products at low cost, we constantly pursue improvement while incorporating new technologies and considering more efficient modes of production. To efficiently process a diverse range of product lines with high quality, we have introduced high-speed machines, multifunctional machines, and automated machines, thereby nurturing technologies that make full use of different types of mechanical power.

By fully operating all of our various facilities around-the-clock, we are able to meet wide-ranging customer requirements, from high-mix, low-volume products to large-lot products, speedily and at low cost.

While constantly responding to the changing times, we thoroughly eliminate waste and build a smoothly managed flow in all stages from receiving orders to shipping, and provide consistent services to customers. Moreover, in manufacturing, we strive to supply products with stable quality and punctual delivery upon building systems for the optimum “flow of materials”.