Our Business

Order → Production → Plating → Coating → Assembly

We work under a uniform management system.

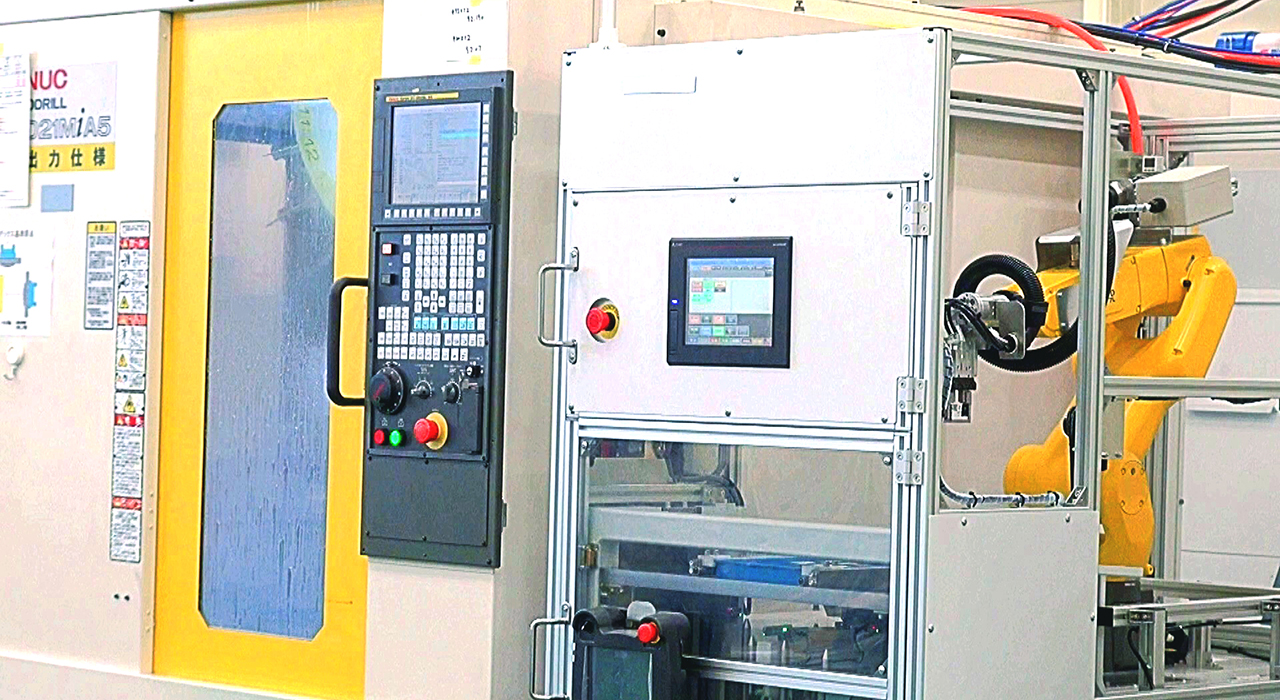

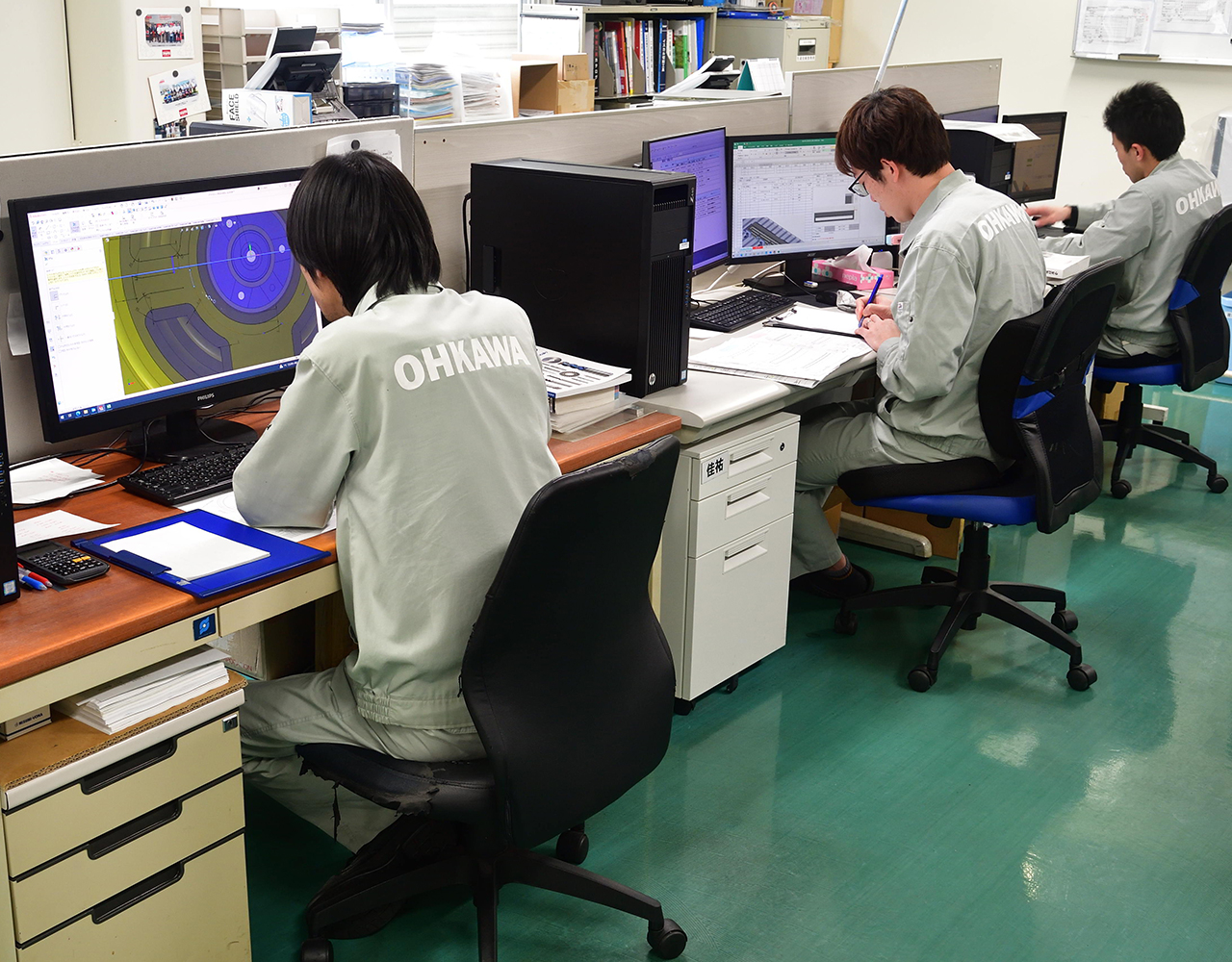

CAD/CAM program

Support manufacturing

with 3D-CAD/CAM systems.

Our experienced programmers make full use of the latest 3D CAD/CAM systems, etc. to create optimal machining programs and achieve faster response.

Furthermore, with automatic processing machines that operate 24 hours a day, we can respond speedily from single items to mass production, and provide customer satisfaction.

Equipment (to our Japanese site)

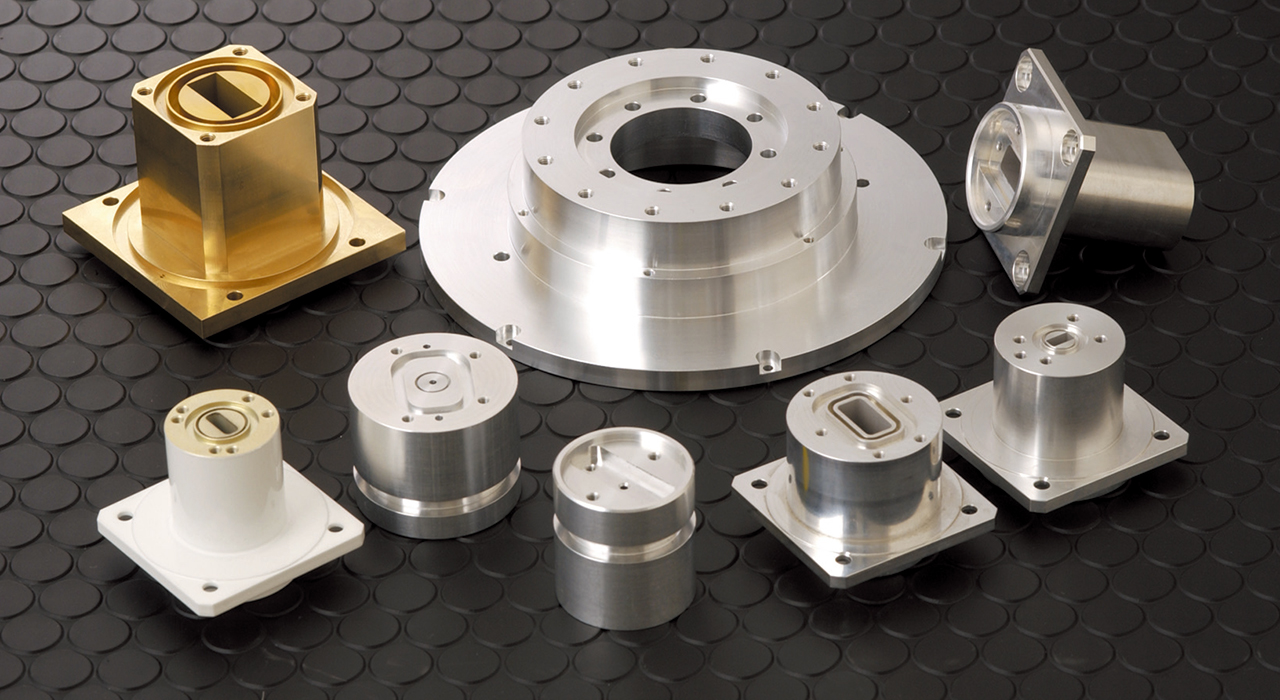

Cutting

Ohkawa’s craftsmen precisely

cut all kinds of materials.

As a specialist in precision cutting, we perform all types of cutting. In addition to our wealth of experience and knowledge, we utilize the application of stable cutting analysis systems, etc., to create a number of products with a high level of technology unrivaled by other companies.

We handle a wide variety of materials, including aluminum, brass, copper, stainless steel, titanium, inconel, and molybdenum.

Turning

Outstanding turning technology based on

accumulated knowledge and experience.

Ohkawa’s craftsmen have a wealth of experience and put their hearts and souls into creating the customer’s wishes. We are also working on high-precision, high-quality manufacturing by utilizing our abundant knowledge and experience in turning processing.

For turning, we use large and small NC lathes and multitasking machines capable of turning, milling, and drilling at the same time to handle a variety of metal processing.

Equipment (to our Japanese site)

Electrical Discharge Machining (EDM)

Achieve high-precision surface processing of all metals.

A group of products that require advanced technology, from precision equipment to aerospace and defense parts. At Ohkawa, we perform high-precision machining using die-sinker EDMs and wire-cut EDMs that incorporate our machining know-how.

Equipment (to our Japanese site)

Finishing/Assembly

Finishing and assembly technology proven

in various fields.

A high level of precision and quality is also required for finishing and assembly under various conditions. Ohkawa has many achievements in mobile and wireless communication equipment, communication equipment for space satellites, aircraft-related equipment, and medical equipment.

Equipment (to our Japanese site)

Precision Cleaning

Parts that should not be contaminated with impurities are ultrasonically cleaned

with ultra-pure water in a clean room,

degassed and double-packaged before shipping.

We perform ultrasonic cleaning with ultra-pure water (10 MΩ·cm or more) in a class 10000 clean room, dry in a clean oven, and then double-pack degassed polyethylene in a class 1000 clean booth. Upon request, particle inspection using UV light (18 mW/cm2, 38 cm distance) is also available. Even for large items that cannot fit in the ultra-pure water (1 0MΩ・cm or more) ultrasonic cleaning tank, an ultra-pure water (10 MΩ·cm or more) shower in a class 10000 clean room can be performed after ultrasonic cleaning with pure water (1 MΩ·cm or more). By doing so, we can prevent the contamination of impurities and perform double packing of degassed polyethylene.

- Ultra-pure water (10 MΩ·cm or more) tank: 700 (W) x 700 (L) x 500 (H)

- Pure water (1 MΩ·cm or more) tank: 1400 (W) x 1400 (L) x 400 (H)

Equipment (to our Japanese site)

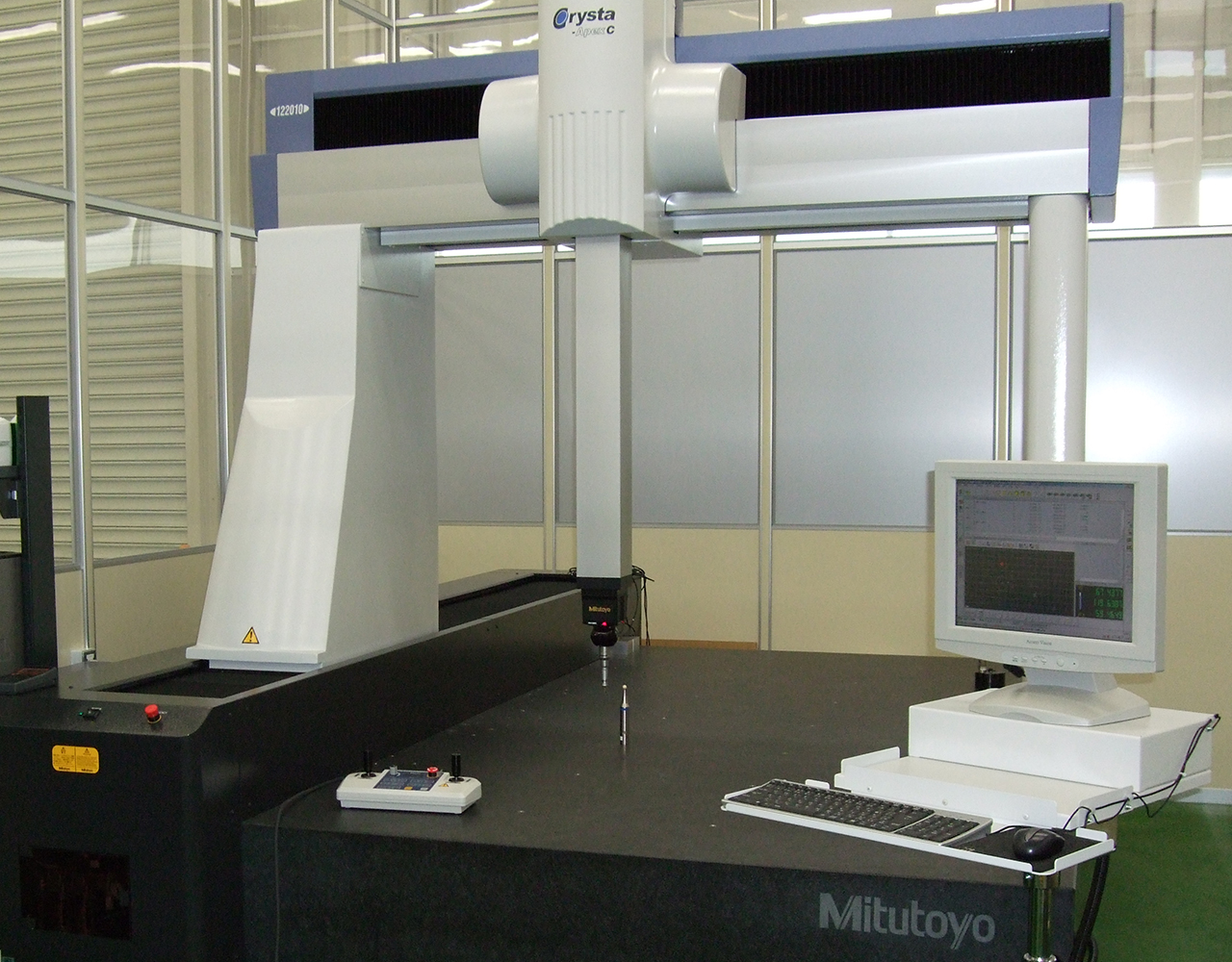

Inspection and Measurement

Advanced measuring instruments such as coordinate measuring

machines further improve product reliability.

As the last step of delivery to the customer, the most important phase is product inspection and measurement. Using various precision measuring instruments such as coordinate measuring machines, digital microscopes, surface roughness measuring instruments, etc., we perform various inspections and measurements from all angles according to each product and conditions.

Equipment (to our Japanese site)